When we explain that Wastex is the tech division of the Coleo Group, the first questions we’re usually asked are:

Is it chemical or mechanical recycling? How do you deal with blends?

How do you decolor the waste?

That’s only natural: disruptive technologies that transform or break down materials tend to be easier to understand and attract more attention than those that, through incremental improvements to existing systems, simply help an industry work better or more efficiently. In other words, which of these two statements is easier to grasp?

- “My technology chemically breaks down polycotton fabrics into polymers and cellulose.”

- “I develop machinery and software that improve the identification of relevant attributes in the textile waste we process at our plants, as well as small-scale machinery to optimize certain processes in weaving and garment factories.”

Even without any background in chemistry, most people will clearly understand the first one better.

And yet, when we take a closer look at why textile recycling hasn’t scaled sufficiently, the explanation rarely lies in the lack of material-transforming technologies. In fact, in recent years we’ve seen major investments in startups tackling exactly those technical challenges, often presented as revolutionary breakthroughs poised to change everything.

And yet here we are — still facing many of the same challenges we did years ago. So what’s going wrong?

A significant part of the problem lies in something much more basic: the gap between the cost of high-quality recycling and what the market is willing to pay. Turning waste into high-value finished material is still, in many cases, more expensive than what brands and consumers are prepared to pay for.

That’s where Wastex comes in. You could say our mission is to reduce that gap — with a radically practical approach. Coleo operates production plants that manage everything from textile waste treatment to the manufacturing of fabrics and garments with high recycled content. And when any part of that chain isn’t competitive enough, Wastex develops technologies to improve its productivity — from traceability software to vision-based machinery and quality control systems.

This pragmatic approach is key to understanding the unique value of our solutions:

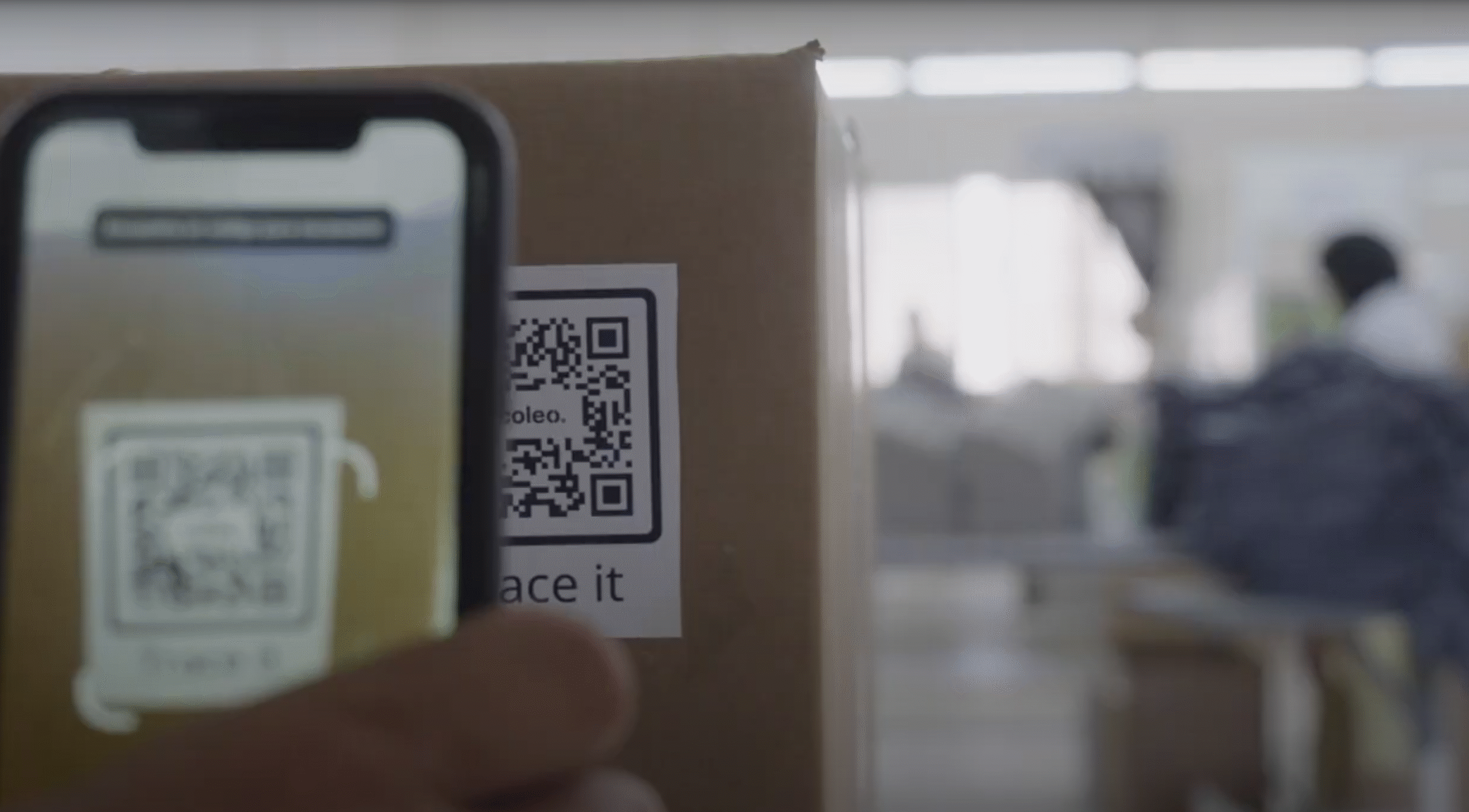

Traceability software

There are excellent companies that have developed digital product passports for brands and consumers, anticipating upcoming regulation. But Wastex built its software from a different place: focused on the needs of our own plants and manufacturing partners when processing and producing recycled materials.

How can we accurately track the origin of materials used by a spinning mill — whether they come from clothing drop-off bins, defective garments, or industrial offcuts — when they’re visually indistinguishable? How do we decide which fiber bales to use for a specific product, aligning quality requirements with the goal of maximizing the use of waste? How do we certify a fabric with more than 90 different material origins for a client — without losing our minds? Or, more recently:

How do we design an effective waste collection system across hundreds of manufacturers, ensuring the material’s quality and that every player in the system fulfills their role?

Machinery

In terms of machinery, there are also major players developing textile classification and quality control equipment. But once again, Wastex takes a different approach. What’s unique about it is that we don’t start from a predefined set of technologies we want to apply to textiles. We start from a deep understanding of the actual problems we face in textile manufacturing and in the waste management plants we’ve operated for the past five years.

From there, we seek the most cost-effective solutions, with a single goal: to make our plants more productive, more competitive, and more sustainable. Our aim isn’t to sell more machines — it is to operate the best recycling and manufacturing plants on the market.

That’s why we say we develop technology from the textile industry, for the textile industry. Because we believe that only those who experience the challenges from within can design solutions that truly make a difference.

Axel Plaza – CTO